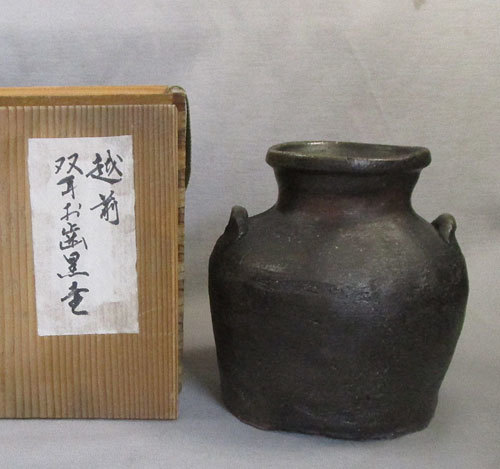

古民具 骨董品 壷 古越前お歯黒壺 江戸時代 骨董

(税込) 送料込み

商品の説明

時代の経過による擦れや汚れ有ります

画像を見て判断して下さい

古い物です気に入ってくださる方

宜しくお願い致します

口径 約7cm

高さ 約11cm

胴径 約13cm

底 約11.5cm商品の情報

| カテゴリー | その他 > アンティーク/コレクション > 工芸品 |

|---|---|

| 商品の色を | ブラック系 / ブラウン系 / オレンジ系 |

| 商品の状態 | やや傷や汚れあり |

未使用品】 古民具 骨董品 壷 古越前お歯黒壺 江戸時代 骨董 工芸品

≪※在庫限り※≫ -お歯黒壺の中古品・新品・未使用品一覧 ヤフオク! 古

2023年最新】お歯黒壺の人気アイテム - メルカリ

≪※在庫限り※≫ -お歯黒壺の中古品・新品・未使用品一覧 ヤフオク! 古

≪※在庫限り※≫ -お歯黒壺の中古品・新品・未使用品一覧 ヤフオク! 古

湖美】越前 おはぐろ 壺 花器 民芸 お歯黒 | monsterdog.com.br

超歓迎お得】 ヤフオク! - r302 越前 お歯黒壺 越前焼 古越前 灰釉

≪※在庫限り※≫ -お歯黒壺の中古品・新品・未使用品一覧 ヤフオク! 古

お歯黒壺、越前、古壺、小壺、緑釉、骨董品、アンティーク、美術品、古美術、備前焼

古民具 骨董品 壷 古越前お歯黒壺 江戸時代 骨董 WEB限定カラー 49.0

お歯黒壺、越前、古壺、小壺、緑釉、骨董品、アンティーク、美術品、古美術、備前焼

お歯黒壺、越前、古壺、小壺、緑釉、骨董品、アンティーク、美術品、古

江戸時代 古越前 お歯黒双耳片口壺 | www.csi.matera.it

≪※在庫限り※≫ -お歯黒壺の中古品・新品・未使用品一覧 ヤフオク! 古

≪※在庫限り※≫ -お歯黒壺の中古品・新品・未使用品一覧 ヤフオク! 古

お歯黒壺 越前焼 江戸時代 小壺 | monsterdog.com.br

越前お歯黒壷 | labiela.com

壷□古備前古いお歯黒壺船壷水瓶古玩古美術時代物骨董品□ | JChere

超歓迎お得】 ヤフオク! - r302 越前 お歯黒壺 越前焼 古越前 灰釉

古い丹波茶壺 四耳壷 江戸時代 骨董 アンティーク 李朝検:古丹波.六古

お歯黒壺 越前焼 江戸時代 小壺 | monsterdog.com.br

越前お歯黒壷 | labiela.com

江戸時代中期 越前古窯 常滑焼き お歯黒壺 | udaytonp.com.br

ヤフオク! -「お歯黒」(アンティーク、コレクション) の落札相場・落札価格

絶品 中国 宋時代 褐釉小壺 古民具 木箱付 送料込み おもちゃ・ホビー

お歯黒壺 越前焼 江戸時代 小壺 | monsterdog.com.br

お歯黒壺、越前、古壺、小壺、緑釉、骨董品、アンティーク、美術品、古

楽天市場】骨董○越前焼お歯黒壺○ | 江戸初期-7世紀頃 |古陶器 | 六古

湖美】越前 おはぐろ 壺 花器 民芸 お歯黒 | monsterdog.com.br

≪※在庫限り※≫ -お歯黒壺の中古品・新品・未使用品一覧 ヤフオク! 古

江戸時代 古越前 お歯黒双耳片口壺 | www.csi.matera.it

湖美】越前 おはぐろ 壺 花器 民芸 お歯黒 | monsterdog.com.br

古窯壺 古丹波 古常滑(〜桃山時代〜) 古道具 古備前 古信楽 骨董 六古

江戸時代 骨董品 応談送料無料 インテリア・住まい・小物 | bca.edu.gr

お歯黒壺、越前、古壺、小壺、緑釉、骨董品、アンティーク、美術品、古

江戸時代 古越前 お歯黒双耳片口壺 | www.csi.matera.it

№16 古越前の壺 江戸時代 美品 越前焼 壺の通販 by Hikosima|ラクマ

レア珍品 江戸 明治時代 上野焼 藁釉緑彩壺22.5cm 茶壺 青流花瓶 古

ポイント2倍 越前の双耳壺 お歯黒壺 | www.sunburyprovidores.com.au

伊賀壷 信楽焼 アンティーク 古道具 古美術-

商品の情報

メルカリ安心への取り組み

お金は事務局に支払われ、評価後に振り込まれます

出品者

スピード発送

この出品者は平均24時間以内に発送しています